In this article a comprehensive textile fiber names are listed, would answer your following questions. Type of Textile Fibers | Classification Textile Fibers | List of Textile Fibers | Textile Fiber Names | Textile Fiber Sources | Kind of Textile Fibers| Textile fibers and their properties | Fibers used for in textiles | Fibers considered as textile | Examples of fibers | Widely used textile fibers | What is textile fiber | Natural Fibers | Man made Fibers | Artificial Fibers

Fiber is a fine hair-like structure and is considered the raw materials of textiles. The fiber is extracted from various sources for commercial use. In addition to obtaining from animals, plants, and minerals, many of the fibers are artificially generated as well. Here is a list of most commonly used textile fibers.

Type of textile fibers can be broadly divided into natural fibers and man-made or chemical fibers. They can be further divided based on the source from where the fibers are obtained.

Fibers are commonly classified as follows (based on the source of the fibers):

| Natural Fibers | Manmade Fibers | |||||

|---|---|---|---|---|---|---|

| Animal Fibers | Plant Fibers | Natural Polymers | Synthetic Polymers | |||

| Hair | Secretion | Seed | Bast | Leaf | ||

|

|

|

|

|

|

|

Natural Fibers

Natural Fibres are nonsynthetic hair-like materials of continuous filaments come from natural growing sources – both plants and animals. Demand for textile fibers such as flax, hemp, jute, kenaf, sisal, and Sugarcane bagasse has increased due to the possibilities of blending with reinforced polymer materials and easy availability of natural fibers.

Animal Fibers

Animal textile fibers commercially used today are generally obtained from the mammals such as Sheep, Goat, Angora Rabbit, Lama, Alpaca, Vicuna, Guanaco, Camel, Yak, Northern American Buffalo, and Musk Ox. The fibers extracted from these animals greatly differ in terms of biological, chemical and physical features. The silk fiber is the only fiber obtained from an insect (secretion) – silkworm.

Animal Hair/Wool Fibers

Sheep Wool

Wool is the common name applied to the soft, curly fibers obtained chiefly from the fleece of domesticated sheep, and used extensively in textile manufacturing. Wool production from sheep is affected by nutrition, climate, and care.Sheep wool categorized by different breeds:

Wool is the common name applied to the soft, curly fibers obtained chiefly from the fleece of domesticated sheep, and used extensively in textile manufacturing. Wool production from sheep is affected by nutrition, climate, and care.Sheep wool categorized by different breeds:- Fine Wool

- Long Wool

- Double coated

Common Sheep Breeds:- Border Leicester

- Cheviot

- Columbia

- Corriedale

- Debouillet

- Delaine-Merino

- Dorset

- Finnsheep

- Hampshire

- Lincoln

- Montadale

- Oxford

- Rambouillet

- Romney, Shropshire

Mohair Wool

Mohair is the fleece produced by Angora goats, generally refers to a silk-like pile fabric or yarn. Most notable for its high luster and sheen, mohair takes to dye exceptionally well and can be blended with other yarns to enhance the quality of the overall textile. The Angora goat is thought to originate from the mountains of Tibet, eventually migrating to Ankara, Turkey by the 16th Century.

Mohair is the fleece produced by Angora goats, generally refers to a silk-like pile fabric or yarn. Most notable for its high luster and sheen, mohair takes to dye exceptionally well and can be blended with other yarns to enhance the quality of the overall textile. The Angora goat is thought to originate from the mountains of Tibet, eventually migrating to Ankara, Turkey by the 16th Century.Alpaca Wool

Alpaca wool is a soft, warmth, and lightweight fiber sheared from Alpaca, a member of the biological family of Camelidae, has loft and is well suited for knitted and crocheted products as well as woven applications. Alpaca fiber has brightness and crimp. The fiber is known for its fineness, luster, lightweight and insulating qualities.Major Alpaca fiber sourcing camelids:

Alpaca wool is a soft, warmth, and lightweight fiber sheared from Alpaca, a member of the biological family of Camelidae, has loft and is well suited for knitted and crocheted products as well as woven applications. Alpaca fiber has brightness and crimp. The fiber is known for its fineness, luster, lightweight and insulating qualities.Major Alpaca fiber sourcing camelids:- The Huacaya

- The Suri

Angora Wool

Angora Wool is a soft keratinous textile material, produced by the long-haired Angora rabbit. Angora fiber is known to be well blended with lamb or sheep wool, primarily to make spinning easier, but also to improve the washing qualities and to increase versatility.Major breeds of Angora rabbits :

Angora Wool is a soft keratinous textile material, produced by the long-haired Angora rabbit. Angora fiber is known to be well blended with lamb or sheep wool, primarily to make spinning easier, but also to improve the washing qualities and to increase versatility.Major breeds of Angora rabbits :- English

- French

- Giant

- Satin

Camel Hair

Camel hair fibers belong to the class of specialty hair fibers with unique characteristics such as luster, softness, warmth, and natural color and sourced from Camels. Camel’s hair blended with wool, silk, and synthetic fibers are considered more valuable.Major fiber sourcing camel varieties.

Camel hair fibers belong to the class of specialty hair fibers with unique characteristics such as luster, softness, warmth, and natural color and sourced from Camels. Camel’s hair blended with wool, silk, and synthetic fibers are considered more valuable.Major fiber sourcing camel varieties.- Arabian ña

- Guanaco

- South America camelid

Cashmere Wool

Cashmere wool is obtained from the Cashmere Goat, which is native in Tibet and in Northern India. It has been sorted according to its natural color, white, gray or brown colors. The raw fiber must be de-haired to separate the fine soft cashmere from coarse and worthless hair.

Cashmere wool is obtained from the Cashmere Goat, which is native in Tibet and in Northern India. It has been sorted according to its natural color, white, gray or brown colors. The raw fiber must be de-haired to separate the fine soft cashmere from coarse and worthless hair.Llama Wool

Llamas, a kind of sheep, are native to areas of high altitude and relatively cool climate with low humidity of the South American Andes. The llama is a two-coated animal. Its fine, downy undercoat gives protection from cold and heat. Llamas do vary considerably in fleece length and thickness, so the importance and frequency of shearing will depend on the individual animal as well as climate.

Llamas, a kind of sheep, are native to areas of high altitude and relatively cool climate with low humidity of the South American Andes. The llama is a two-coated animal. Its fine, downy undercoat gives protection from cold and heat. Llamas do vary considerably in fleece length and thickness, so the importance and frequency of shearing will depend on the individual animal as well as climate.Qiviut Wool

Musk oxen belong to Bovidae family which includes bison, buffalo, antelope as well as domesticated sheep, cattle and goats. Qiviut fiber is long with a diameter of 12 – 18 microns which makes it even softer than average cashmere. Much warmer than wool, it is worn as an insulating layer in clothing because it wicks moisture from the body and doesn’t shrink or felt.

Musk oxen belong to Bovidae family which includes bison, buffalo, antelope as well as domesticated sheep, cattle and goats. Qiviut fiber is long with a diameter of 12 – 18 microns which makes it even softer than average cashmere. Much warmer than wool, it is worn as an insulating layer in clothing because it wicks moisture from the body and doesn’t shrink or felt.Chiengora Hair

Any dog fiber with a staple longer than 2-3 inches can be used to make yarn, although longer fibers are easier to spin and make for more durable garments. Shorter fibers can be carded with silk or wool to be made into yarn. Dogs with particularly long hair and dual coats, like Samoyed or Great Pyrenees are best for fiber production.

Any dog fiber with a staple longer than 2-3 inches can be used to make yarn, although longer fibers are easier to spin and make for more durable garments. Shorter fibers can be carded with silk or wool to be made into yarn. Dogs with particularly long hair and dual coats, like Samoyed or Great Pyrenees are best for fiber production.Yak Wool

Textile products made of yak wool is highly competitive with cashmere in terms of quality. Regarded as one of the remarkable domestic animals, yak thrives in cold climatic conditions that tower the highest elevations.Yak varieties:

Textile products made of yak wool is highly competitive with cashmere in terms of quality. Regarded as one of the remarkable domestic animals, yak thrives in cold climatic conditions that tower the highest elevations.Yak varieties:- Arhangai

- Bayanhongor

- Zavhan

- Uvurhangai

Vicuña Wool

Vicuñas produce the finest animal fiber in the world. The vicuña is a South American Camelid belonging to the infra-order Tylopoda, and family Camelidae. Vicuñas are the only truly wild species that can be captured, sheared and re-released on a commercial basis. Vicuña has been protected by the International Convention for the Trade of Endangered Species (CITES) since 1973 and by the Vicuña Convention signed by Argentina, Bolivia, Chile, and Perú since 1979.

Vicuñas produce the finest animal fiber in the world. The vicuña is a South American Camelid belonging to the infra-order Tylopoda, and family Camelidae. Vicuñas are the only truly wild species that can be captured, sheared and re-released on a commercial basis. Vicuña has been protected by the International Convention for the Trade of Endangered Species (CITES) since 1973 and by the Vicuña Convention signed by Argentina, Bolivia, Chile, and Perú since 1979.

Animal Secretion Fibers

Silk Fiber

Silk fibers are natural fibrous protein-based materials, spun by Lepidoptera larvae such as silkworms, spiders, scorpions, mites, and flies. Recently silk is preferred for biomedical, textile and biotechnology industries due to its unique non-toxicity, biocompatibility, and biodegradability properties.Silk is rightly called the queen of textiles for its luster, sensuousness, and glamour. The silk rival with the most advanced synthetic polymers, yet the production of silk does not require harsh processing conditions.

Silk fibers are natural fibrous protein-based materials, spun by Lepidoptera larvae such as silkworms, spiders, scorpions, mites, and flies. Recently silk is preferred for biomedical, textile and biotechnology industries due to its unique non-toxicity, biocompatibility, and biodegradability properties.Silk is rightly called the queen of textiles for its luster, sensuousness, and glamour. The silk rival with the most advanced synthetic polymers, yet the production of silk does not require harsh processing conditions.

Plant/Vegetable/Cellulosic Fibers

Natural plant fibers are cell walls that occur in the stem, wood, and leaf parts and are comprised of cellulose, hemicelluloses, lignins and aromatics, waxes and other lipids, ash and water-soluble compounds attached in a specific way. Plant fibers are classified into two groups: soft fibers and hard fibers.

Plant Seed Fibers

Cotton Fiber

Cotton is a vegetable fiber which surrounds the seeds of the cotton plant, a shrub in the Malvaceae family. The fiber is generally transformed into yarn which is woven to manufacture fabrics. Cotton has been used for millennia in the confection of fabric, with the earliest known use dating from 12,000 years B.C. in Egypt.Classification is used to determine the quality of the cotton fiber in terms of length, uniformity, strength, micronaire, and color. Cotton classification (and quality) can also be affected by trash content, leaf grade, and the presence of extraneous matter.

Cotton is a vegetable fiber which surrounds the seeds of the cotton plant, a shrub in the Malvaceae family. The fiber is generally transformed into yarn which is woven to manufacture fabrics. Cotton has been used for millennia in the confection of fabric, with the earliest known use dating from 12,000 years B.C. in Egypt.Classification is used to determine the quality of the cotton fiber in terms of length, uniformity, strength, micronaire, and color. Cotton classification (and quality) can also be affected by trash content, leaf grade, and the presence of extraneous matter.Coir Fiber

Coir is a durable fiber extracted from discarded coconut husks. Coir or coconut Fibre belongs to the group of hard structural fibers. Coir fibers are categorized in two ways.One distinction is based on whether they are recovered from ripe or immature coconut husks.

Coir is a durable fiber extracted from discarded coconut husks. Coir or coconut Fibre belongs to the group of hard structural fibers. Coir fibers are categorized in two ways.One distinction is based on whether they are recovered from ripe or immature coconut husks.- The husks of fully ripened coconuts yield brown coir. Strong and highly resistant to abrasion, its method of processing also protects it from the damaging ultraviolet component of sunlight. Dark brown in color, it is used primarily in brushes, floor mats, and upholstery padding.

- White coir comes from the husks of coconuts harvested shortly before they ripen. Light brown or white in color, this fiber is softer and less strong than brown coir. It is usually spun into yarn, which may be woven into mats or twisted into twine or rope.

Kapok Fiber

Pod Ceiba Safed Semal White Silk-cotton Tree Kapok Kapok fiber is a natural and environmental-friendly cellulosic fiber with a lightweight of volume units, hollow structure. Kapok fiber is soft silky cellulosic fiber but has a significantly homogeneous hollow tube shape.Kapok is considered unsuitable for textile purposes because the fiber is brittle, smooth and slippery. They are used in bedding, upholstery industries, in the production of life-saving equipment and in the construction of thermally insulated and soundproof covers and walls.

Plant Bast Fibers

Bast consists of a wood core surrounded by a stem. Within the stem, there are a number of fibers bundles, each containing individual fiber cells. The filaments are made up of cellulose and hemicelluloses, bonded together by lignin and pectin.

Jute Fiber

Jute is a natural fiber with golden and silky shine because of which also called as the golden fiber. It is one of the cheapest vegetable fibers obtained from the bast or skin of plant’s stem. Jute is mainly extracted from the stem of white jute plant (Corchorus capsularis) and from Tossa jute (C.olitorius).Jute is a natural biodegradable fiber with advantages such as high tensile strength, excellent thermal conductivity, coolness, ventilation function. Jute has high specific properties, low density, less abrasive behavior to the processing equipment, good dimensional stability, and harmlessness. Jute is multicelled with the cell wall of the fiber is made up of a number of layers.

Jute is a natural fiber with golden and silky shine because of which also called as the golden fiber. It is one of the cheapest vegetable fibers obtained from the bast or skin of plant’s stem. Jute is mainly extracted from the stem of white jute plant (Corchorus capsularis) and from Tossa jute (C.olitorius).Jute is a natural biodegradable fiber with advantages such as high tensile strength, excellent thermal conductivity, coolness, ventilation function. Jute has high specific properties, low density, less abrasive behavior to the processing equipment, good dimensional stability, and harmlessness. Jute is multicelled with the cell wall of the fiber is made up of a number of layers.Flax/Linen Fiber

Flax is the plant that produces the bast fiber that is made into linen. Linen fiber is plant fiber collected from the phloem (the “inner bark”) or bast surrounding the stem of certain, mainly dicotyledons, plants. They support the conductive cells of the phloem and provide strength to the stem. Hemp fiber contains the phenolic substance, so it has anti-moldy and bacteriostatic properties.

Flax is the plant that produces the bast fiber that is made into linen. Linen fiber is plant fiber collected from the phloem (the “inner bark”) or bast surrounding the stem of certain, mainly dicotyledons, plants. They support the conductive cells of the phloem and provide strength to the stem. Hemp fiber contains the phenolic substance, so it has anti-moldy and bacteriostatic properties.Hemp Fiber

Hemp is a fast‐growing plant that generally requires little or no chemical herbicides and pesticides. Hemp can be processed as a bast fiber, or as a regenerated fiber. Hemp is a member of the Cannabaceae family and is a plant which produces bast fibers. Hemp (also known as Cannabis) was one of the first plants to be cultivated by the human race and was previously considered to be one of the most important agricultural crops.

Hemp is a fast‐growing plant that generally requires little or no chemical herbicides and pesticides. Hemp can be processed as a bast fiber, or as a regenerated fiber. Hemp is a member of the Cannabaceae family and is a plant which produces bast fibers. Hemp (also known as Cannabis) was one of the first plants to be cultivated by the human race and was previously considered to be one of the most important agricultural crops.Banana Fiber

All varieties of banana plants have fibers in abundance that fall under bast fibers category. The fibers are collected after the fruit is harvested from the trunk of the banana plant (pseudostem), which usually is usually thrown as an agricultural waste.

All varieties of banana plants have fibers in abundance that fall under bast fibers category. The fibers are collected after the fruit is harvested from the trunk of the banana plant (pseudostem), which usually is usually thrown as an agricultural waste.Ramie Fiber

Ramie is one of the strongest natural fibers. It exhibits even greater strength when wet. Ramie fiber is known especially for its ability to hold shape, reduce wrinkling, and introduce a silky luster to the fabric appearance. It is not as durable as other fibers, and so is usually used as a blend with other fibers such as cotton or wool.It is similar to flax in absorbency, density, and microscopic appearance. Because of its high molecular crystallinity, ramie is stiff and brittle and will break if folded repeatedly in the same place; it lacks resiliency and is low in elasticity and elongation potential.

Ramie is one of the strongest natural fibers. It exhibits even greater strength when wet. Ramie fiber is known especially for its ability to hold shape, reduce wrinkling, and introduce a silky luster to the fabric appearance. It is not as durable as other fibers, and so is usually used as a blend with other fibers such as cotton or wool.It is similar to flax in absorbency, density, and microscopic appearance. Because of its high molecular crystallinity, ramie is stiff and brittle and will break if folded repeatedly in the same place; it lacks resiliency and is low in elasticity and elongation potential.Kenaf Fiber

Kenaf fiber is a natural fiber extracted from Hibiscus cannabinus L. The kenaf trunks need to be retted in order to extract the fiber. Kenaf fiber possesses excellent tensile and flexural strength when compared with other natural fibers.

Kenaf fiber is a natural fiber extracted from Hibiscus cannabinus L. The kenaf trunks need to be retted in order to extract the fiber. Kenaf fiber possesses excellent tensile and flexural strength when compared with other natural fibers.Sugarcane bagasse

Sugarcane is a plant which grows up to 6 meters high and has a diameter up to 6 cm, and the bagasse is the fibrous residue which is obtained from sugarcane processing after extraction of the juice from the cane stalk.

Plant Leaf Fibers

Piña Fiber

Pineapple leaf fiber is one kind of fiber derived from the leaves of the pineapple plant. From a large selection of plant fibers, pineapple leaf fibers obtained from the leaves of pineapple plant of Josapine have the highest cellulose contents which make the fibers mechanically sound.Pineapple Leaf Fiber exhibit excellent mechanical properties due to rich cellulose content of more than 70% which are potential to be used as reinforcement in polymer composites.

Pineapple leaf fiber is one kind of fiber derived from the leaves of the pineapple plant. From a large selection of plant fibers, pineapple leaf fibers obtained from the leaves of pineapple plant of Josapine have the highest cellulose contents which make the fibers mechanically sound.Pineapple Leaf Fiber exhibit excellent mechanical properties due to rich cellulose content of more than 70% which are potential to be used as reinforcement in polymer composites.Sisal Fiber

The sisal fibers obtained from the leaf of sisal plants are white/golden white in color. They can be twisted into yarns and ropes in wet conditions. Fiber thickness, length, and strength depend upon the age and location of the plant. The length varied from 0.5m to 1m and diameter is 43 between 0.21mm to 0.29mm. The density of the fiber was found to be around 1.51 g/ cm3.

The sisal fibers obtained from the leaf of sisal plants are white/golden white in color. They can be twisted into yarns and ropes in wet conditions. Fiber thickness, length, and strength depend upon the age and location of the plant. The length varied from 0.5m to 1m and diameter is 43 between 0.21mm to 0.29mm. The density of the fiber was found to be around 1.51 g/ cm3.Raffia Fiber

Raffia fibers are leaf fibers obtained raffia palms. Raffia fabrics are used for everyday garments or “ceremonial costumes” among some ethnic groups of Central Africa from the coast of the Gulf of Guinea.Raffia is a plant that belongs to a palm genus that originated from Madagascar and grows in tropical rainforests, along river banks of the savannah, marshes, and swamps in the areas stretching from Madagascar, where it originated, to the Congo and Gabon of Central Africa, Cameroon, Nigeria, and Liberia alongside of the Gulf of Guinea.

Raffia fibers are leaf fibers obtained raffia palms. Raffia fabrics are used for everyday garments or “ceremonial costumes” among some ethnic groups of Central Africa from the coast of the Gulf of Guinea.Raffia is a plant that belongs to a palm genus that originated from Madagascar and grows in tropical rainforests, along river banks of the savannah, marshes, and swamps in the areas stretching from Madagascar, where it originated, to the Congo and Gabon of Central Africa, Cameroon, Nigeria, and Liberia alongside of the Gulf of Guinea.Abaca Fiber

Abaca is a leaf fiber which belongs to the banana family of plants with more tapering the leaves than Banana and is cheap and abundantly available. Known as Manila Hemp Abaca is a hard fiber. Abaca is the strongest of all natural fibers.Abaca fiber is extracted from the leaf sheath traditionally by stripping using either manual or mechanical process. Volcanic areas are suited for abaca cultivation the Philippines tropical climate. It has a lot of applications in the household as well as technical areas.

Abaca is a leaf fiber which belongs to the banana family of plants with more tapering the leaves than Banana and is cheap and abundantly available. Known as Manila Hemp Abaca is a hard fiber. Abaca is the strongest of all natural fibers.Abaca fiber is extracted from the leaf sheath traditionally by stripping using either manual or mechanical process. Volcanic areas are suited for abaca cultivation the Philippines tropical climate. It has a lot of applications in the household as well as technical areas.

Mineral Fibers

Asbestos Fiber

Asbestos is a mineral. It is a natural rock mined from the ground. Asbestos fibers are very light. Asbestos was used in a variety of residential and commercial building products including floor tile; ceiling tile; sound and thermal insulation; siding; roofing; spackling; plaster and stucco; and paints.Types of Asbestos:

Asbestos is a mineral. It is a natural rock mined from the ground. Asbestos fibers are very light. Asbestos was used in a variety of residential and commercial building products including floor tile; ceiling tile; sound and thermal insulation; siding; roofing; spackling; plaster and stucco; and paints.Types of Asbestos:- Chrysotile/ white asbestos

- Amosite/ brown asbestos

- Crocidolite/ blue asbestos

Glass/Fiberglass Fiber

Glass melts are made by fusing (co-melting) silica with minerals, which contain the oxides needed to form a given composition. The molten mass is rapidly cooled to prevent crystallization and formed into glass fibers by a process also known as fiberization.

Glass melts are made by fusing (co-melting) silica with minerals, which contain the oxides needed to form a given composition. The molten mass is rapidly cooled to prevent crystallization and formed into glass fibers by a process also known as fiberization.

Manmade Fibers

Man-made fibers are fibers in which either the basic chemical units have been formed by chemical synthesis followed by fiber formation or the polymers from natural sources have been dissolved and regenerated after passage through a spinneret to form fibers. This fiber came to success when the researchers obtained a product by condensation of molecules presenting two reactive aminic groups with molecules characterized by two carboxylic reactive groups.

Fibers from Natural Polymers

Bamboo Fiber

Bamboo is the vernacular term for perennial, giant woody evergreen plants in the grass family Poaceae. Bamboo is a natural lignocellulosic fiber obtained from bamboo culm. Its chemical composition is similar to bast fiber so, its structure and properties are often compared with other bast fibers such as flax and jute.

Bamboo is the vernacular term for perennial, giant woody evergreen plants in the grass family Poaceae. Bamboo is a natural lignocellulosic fiber obtained from bamboo culm. Its chemical composition is similar to bast fiber so, its structure and properties are often compared with other bast fibers such as flax and jute.Modal Fiber

Lenzing is a company that produces Lenzing Modal® fibers, which is extracted from beech wood. Modal Fiber is very soft, shiny in nature and silk feel than mercerized cotton with the ability to absorb up to 50% more water than cotton.

Lenzing is a company that produces Lenzing Modal® fibers, which is extracted from beech wood. Modal Fiber is very soft, shiny in nature and silk feel than mercerized cotton with the ability to absorb up to 50% more water than cotton.Lyocell Fiber

The cellulose fibers produced by direct dissolution have the generic name of lyocell. Lyocell is similar in strength to polyester and stronger than cotton and all other man-made staple fiber cellulosic. It also has very high dry and a wet module for cellulosic fiber in both the dry and wet states.

The cellulose fibers produced by direct dissolution have the generic name of lyocell. Lyocell is similar in strength to polyester and stronger than cotton and all other man-made staple fiber cellulosic. It also has very high dry and a wet module for cellulosic fiber in both the dry and wet states.Rayon Fiber

In the production of Rayon Fiber, purified cellulose is chemically converted into a soluble compound. A solution of this compound is passed through the spinneret to form soft filaments that are then converted or “regenerated” into almost pure cellulose. Because of the reconversion of the soluble compound to cellulose, Rayon is referred to as a regenerated cellulose fiber.Purified cellulose for Rayon production usually comes from specially processed wood pulp and is called “dissolving cellulose” or “dissolving pulp” to distinguish it from lower grade wood pulps used for papermaking and other purposes.

In the production of Rayon Fiber, purified cellulose is chemically converted into a soluble compound. A solution of this compound is passed through the spinneret to form soft filaments that are then converted or “regenerated” into almost pure cellulose. Because of the reconversion of the soluble compound to cellulose, Rayon is referred to as a regenerated cellulose fiber.Purified cellulose for Rayon production usually comes from specially processed wood pulp and is called “dissolving cellulose” or “dissolving pulp” to distinguish it from lower grade wood pulps used for papermaking and other purposes.Acetate Fiber

There are two types of cellulose-based fibers; regenerated/pure cellulose (such as the fibers from the cupro-ammonium process) and modified cellulose (such as the cellulose acetates and rayon).Acetate is derived from cellulose by breaking down wood pulp (dissolving pulp) into purified cellulose. By reacting the purified cellulose with acetic acid and acetic anhydride, whilst using sulfuric acid as a catalyst, cellulose acetate dope is produced.

There are two types of cellulose-based fibers; regenerated/pure cellulose (such as the fibers from the cupro-ammonium process) and modified cellulose (such as the cellulose acetates and rayon).Acetate is derived from cellulose by breaking down wood pulp (dissolving pulp) into purified cellulose. By reacting the purified cellulose with acetic acid and acetic anhydride, whilst using sulfuric acid as a catalyst, cellulose acetate dope is produced.

Fibers from Synthetic Polymers

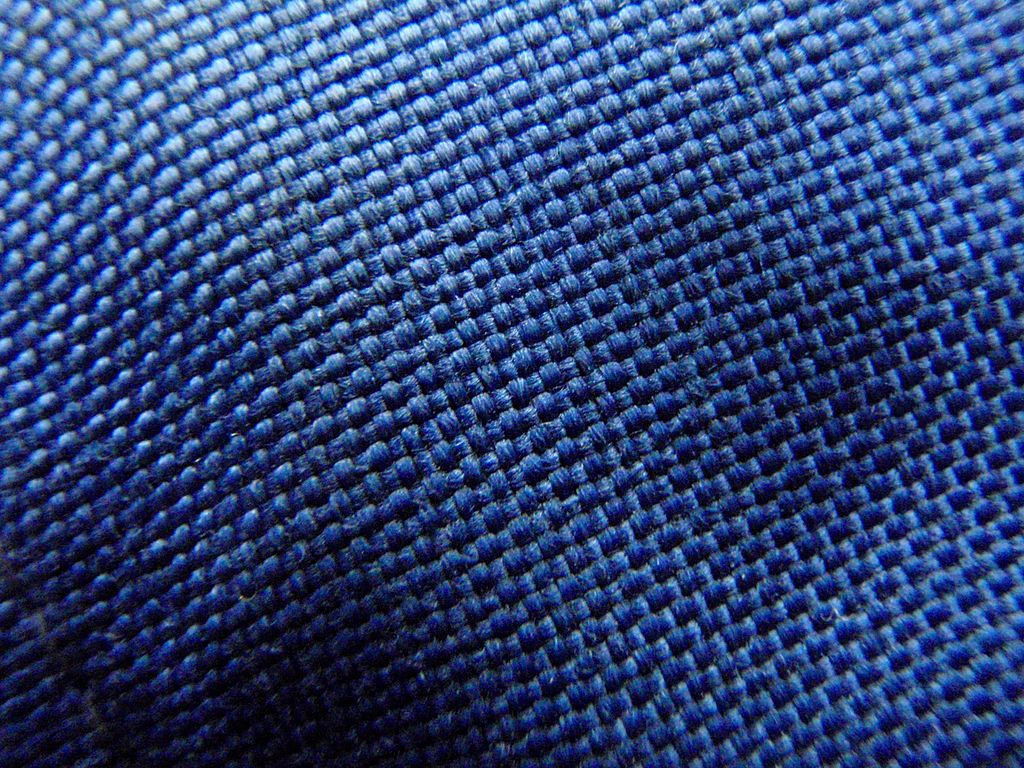

Polyester Fiber

Polyester is a Synthetic, Non-Renewable Fiber derived from petroleum. Polyester has surpassed cotton as the most commonly produced fiber. They are used in varying applications ranging from apparel, home textiles or can be processed to be used in industrial applications.

Polyester is a Synthetic, Non-Renewable Fiber derived from petroleum. Polyester has surpassed cotton as the most commonly produced fiber. They are used in varying applications ranging from apparel, home textiles or can be processed to be used in industrial applications.Nylon Fiber

Nylon a Polyamide, it is a condensation polymer. Nylon is thermoplastic silky materials that can be melt processed into fibers, films or shapes. Nylon is a tough material that is difficult to tear and exhibits excellent abrasion resistance. Nylon fibers were the first truly synthesized manufactured fibers; introduced in the 1930s as a replacement for boar bristles in toothbrushes, nylon fiber quickly found itself adapted into several forms of manufactured items.

Nylon a Polyamide, it is a condensation polymer. Nylon is thermoplastic silky materials that can be melt processed into fibers, films or shapes. Nylon is a tough material that is difficult to tear and exhibits excellent abrasion resistance. Nylon fibers were the first truly synthesized manufactured fibers; introduced in the 1930s as a replacement for boar bristles in toothbrushes, nylon fiber quickly found itself adapted into several forms of manufactured items.Spandex Fiber

Spandex is the generic name for synthetic fiber, whose fiber-forming substance is a long chain synthetic polymer. Spandex fibers exhibit superior stretch and elastic recovery ability, providing garments containing spandex fibers with good fitting and comfort characteristics.

Spandex is the generic name for synthetic fiber, whose fiber-forming substance is a long chain synthetic polymer. Spandex fibers exhibit superior stretch and elastic recovery ability, providing garments containing spandex fibers with good fitting and comfort characteristics.Acrylic Fiber

Acrylic fibers are synthetic fibers made from a polyacrylonitrile polymer. Acrylic fibers are the third largest class of synthetic fiber after polyester and nylons.Kevlar Fiber

Kevlar aramid fiber was developed by DuPont scientists researching liquid crystalline polymer solutions. Kevlar is a manmade fiber, it as an organic fiber in aromatic polyamide family. Kevlar is made by a condensation reaction of an amine (1, 4-phenylenediamine) and acid chloride (terephthaloyl chloride).

Kevlar aramid fiber was developed by DuPont scientists researching liquid crystalline polymer solutions. Kevlar is a manmade fiber, it as an organic fiber in aromatic polyamide family. Kevlar is made by a condensation reaction of an amine (1, 4-phenylenediamine) and acid chloride (terephthaloyl chloride).